Fhole Bender

Since I’ve been on benders lately, I’d thought I’d share this one 🙄🤓. This one is similar to my gravity bender in that the finished form is what I’m using to bend the wood around.

I’ve tried everything with fhole bending: bushings, soldering guns, bolts and blow torches, jigs that attached to my bending pipe, adjusting thicknesses, wood grain, and even the microwave! The common thread to success with any of them was supporting the bend as much as possible and that’s really hard to do on such a tiny radius with a thickness of wood that just doesn’t want to bend that much. The more support, the more success!

The idea of this jig evolved from a previous one where I tried squeezing the wood against a hot metal bushing with a cam mounted against it and it sat on top of my iron (I included pics of it). It worked quite well but i knew it wasn’t 100% there. This new bender is full proof and now I can’t wait to get to my next fholes! The feeling of ease as it’s pulling around that tight upper eye is so rewarding and it makes the time it took to make the jig totally worth it.

It has 2- 50Watt heater cartridges in it, one right in the center of the fhole eye as well as the thermocoupler right next to it so I can easily monitor and control the temp.

Side note- this was my ever first attempt at milling aluminum on my CNC. It was a huge learning experience and I’m very grateful to @fink.instruments for his help and emotional support through the process. There were definitely a few hairy moments 😉 if I had those moments in camera I’d certainly share those!

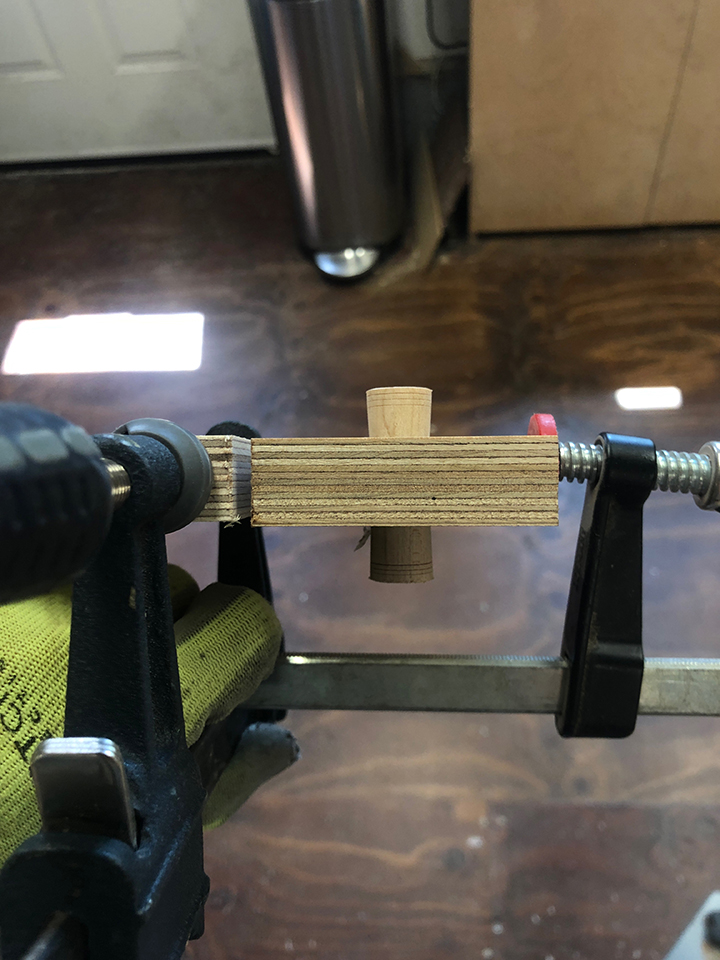

A thin stainless steel strap and locking wedge allow constant support, which is why this works so well

I’ve always laminated my bindings prior to glueing into the top; less fuss and easier install (especially when there are only two mitres in the overall assembly).

Normally, we see Fhole bindings thin out as they wrap around the tight bends, this new bending method alleviates the need from doing that and the overall look is much more uniform.

Stay Connected