Binding an Fhole

Installing wood binding in fholes can be a tricky job. This method is straight forward and allows one to do a lot of the work off of the guitar in order to get a clean result when time for glueing. My fholes have two edges or binding strips, for other fhole designs this method would work just as well. I bend the wood strips on smaller steel shafts off an electric bender and put them into a mold. Once cool, I laminate the other binding veneers in the same mold. The dry binding strips are then ready to be installed into each fhole.

When I thickness my main outer binding, I taper the piece of wood slightly at one end. This slight thinning makes it easier to pull around the hot pipe and conform to the tight fhole eyes without creasing or breaking. I also test out pieces of wood before I choose it for binding to make sure it bends significantly well without being a total pain in the butt.

Binding an fhole with wood is one of those steps that takes patience. Here’s a pretty straight forward setup that makes it a little easier to install with a cleaner result.

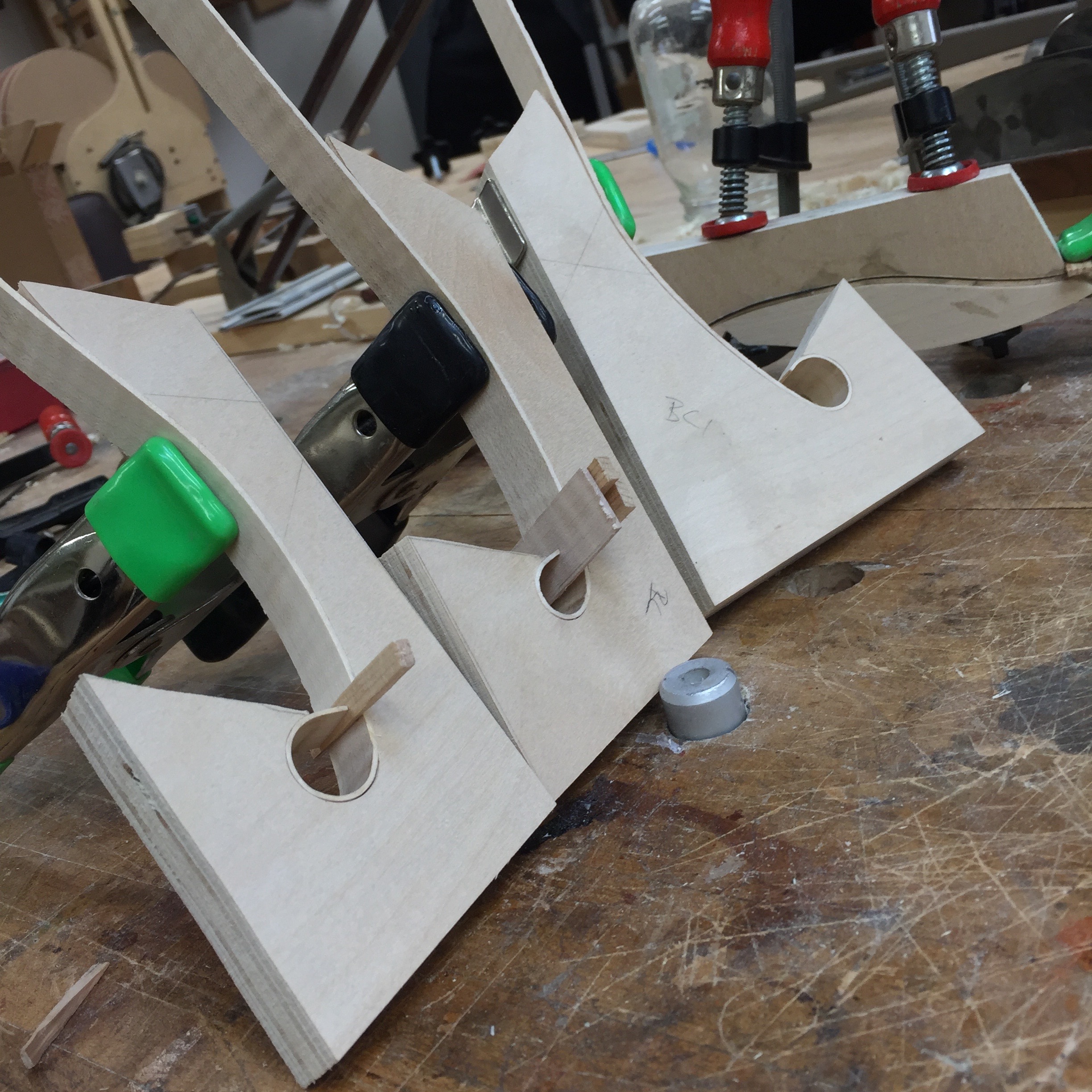

Here is the positive and negative mold in use. I have a few of these large paint brushes that have the slightest taper, the perfect wedge to tighten the eye. The wedge drives it even tighter. (Don’t forget to wax your mold!)

More glue, more tape, more wedge. I’ll partially glue the lower eye and half the binding, then I’ll get the miter perfectly cut, and then finish the glue up.

Stay Connected